In every refrigeration system, the condensing unit is the workhorse that drives cooling efficiency and reliability. At ColdTech Group, we engineer high-performance condensing units designed for cold rooms, freezers, and industrial applications where precision and durability are non-negotiable.

What is a Condensing Unit?

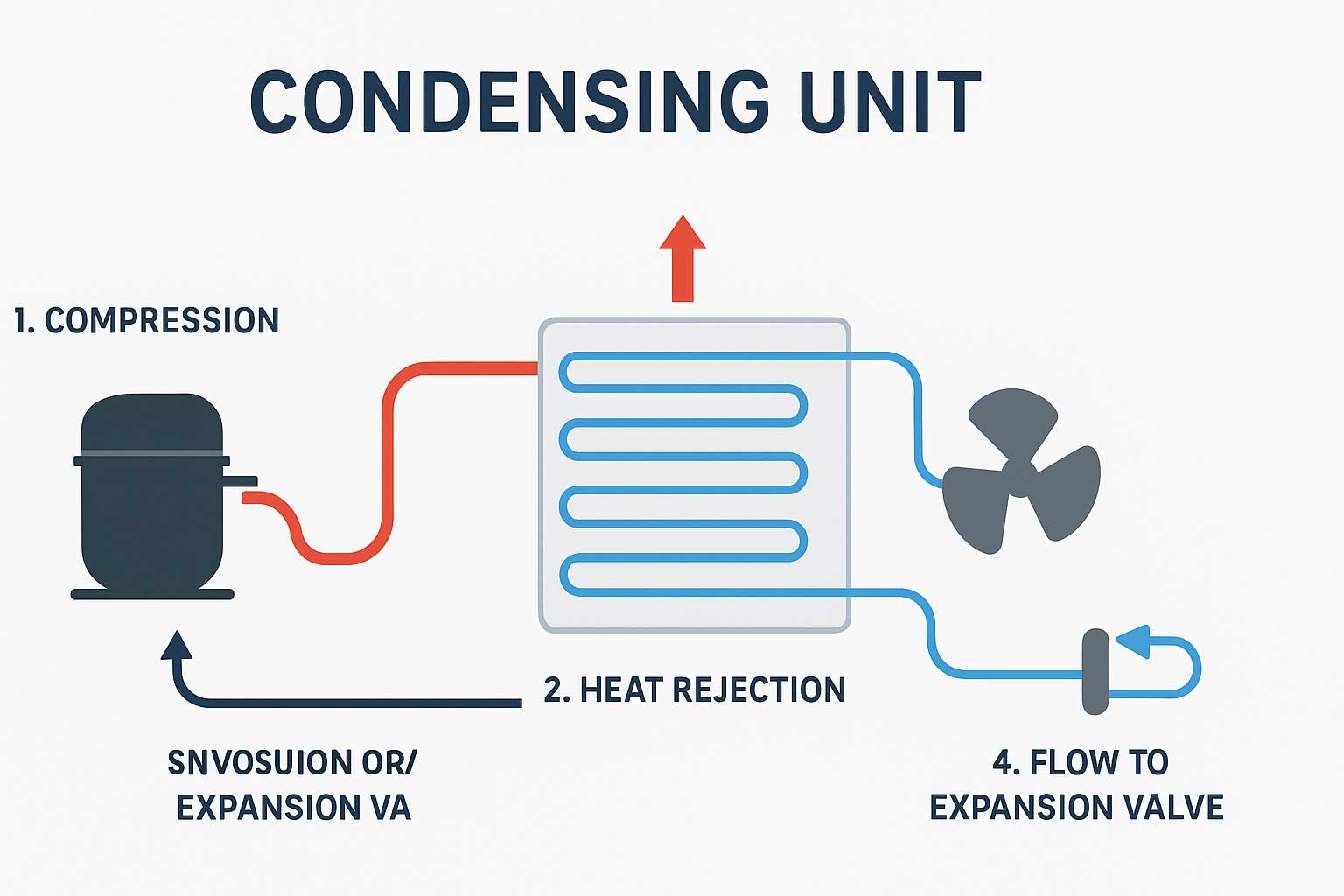

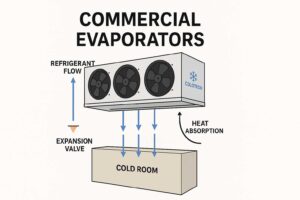

A condensing unit is the engine of a refrigeration system. It houses the compressor, condenser coil, and fan, working together to release heat absorbed from the evaporator into the surrounding environment. Without a reliable condensing unit, the refrigeration cycle cannot function effectively.

How Does It Work?

- Compression – The compressor receives low-pressure refrigerant vapor from the evaporator and compresses it into high-pressure, high-temperature gas.

- Heat Rejection – This gas passes through the condenser coil, where fans remove heat and cool it down.

- Condensation – The refrigerant changes from gas to liquid as it loses heat.

- Flow to Expansion Valve – The high-pressure liquid refrigerant moves to the expansion valve to restart the cooling cycle.

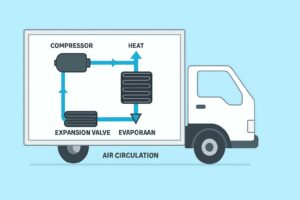

This continuous cycle ensures stable and efficient operation of cold rooms and freezers.

Types of Condensing Units

ColdTech Group provides a wide range of condensing units suited to different environments:

- Air-Cooled Condensing Units – Compact, cost-effective, and widely used in commercial refrigeration.

- Water-Cooled Condensing Units – Ideal where water supply is available; efficient in high-ambient conditions.

- Remote Condensing Units – Located outside the storage area to minimize noise and heat buildup inside.

- Customized Units – Engineered for specialized industries like pharmaceuticals, hospitality, and cold chain logistics.

Key Technical Features to Consider

When selecting a condensing unit, efficiency and durability are critical. Important aspects include:

- Compressor Type: Scroll, semi-hermetic, or screw depending on capacity requirements.

- Capacity (TR/kW): Must match the size and load of the refrigeration system.

- Refrigerant Compatibility: Designed for eco-friendly refrigerants to meet global standards.

- Noise Level: Low-noise motors and vibration-resistant designs for indoor or urban applications.

- Durability: Weather-resistant coatings and robust construction ensure long service life.

Why Choose ColdTech Condensing Units?

Our condensing units are engineered to deliver:

- Energy Efficiency – Optimized compressor and fan designs reduce operating costs.

- High Reliability – Built with quality components for continuous operation in demanding conditions.

- Flexibility – Available in multiple configurations and capacities.

- Sustainability – Compatible with modern refrigerants that meet environmental norms.

Applications Across Industries

ColdTech condensing units are widely used in:

- Cold rooms and freezers

- Supermarkets and hypermarkets

- Hotels and restaurants

- Food and beverage processing plants

- Dairy, meat, and seafood storage

- Pharmaceutical cold chain logistics

Conclusion

Condensing units are the heart of refrigeration systems, ensuring that industries dependent on cold storage can operate smoothly. At ColdTech Group, we combine engineering excellence, advanced technology, and durable design to provide condensing units that guarantee performance, efficiency, and long-term reliability.

Recent Comments