When it comes to refrigeration, the evaporator plays a central role in ensuring consistent cooling and energy efficiency. At ColdTech Group, we specialize in providing advanced refrigeration solutions—and commercial evaporators are one of the most critical components in any cold storage system.

What is a Commercial Evaporator?

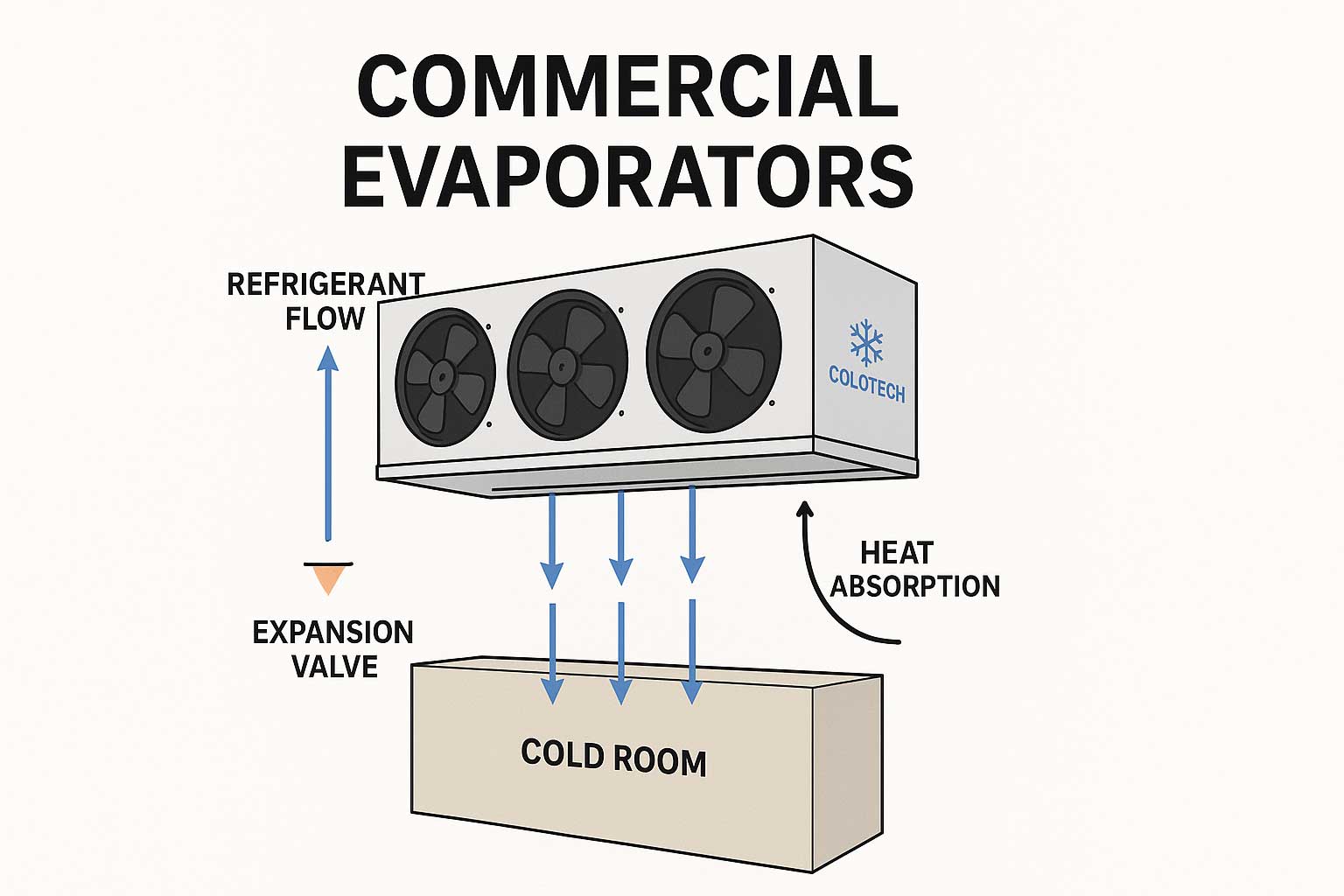

A commercial evaporator is a heat exchanger that absorbs heat from the surrounding air inside a cold room, freezer, or refrigeration unit. By circulating refrigerant through its coils, it removes unwanted heat and maintains the precise temperature required for food storage, pharmaceuticals, industrial processes, and more.

How Does It Work?

- Refrigerant Flow – The evaporator receives low-pressure liquid refrigerant from the expansion valve.

- Heat Absorption – Warm air inside the cold room passes over the evaporator coils with the help of fans.

- Phase Change – The refrigerant absorbs heat and evaporates into a gas.

- Air Circulation – Fans distribute the cooled air evenly across the storage area.

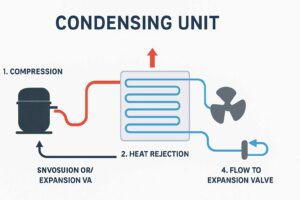

- Cycle Continuation – The gaseous refrigerant returns to the compressor to repeat the cycle.

This process ensures the cold room remains at stable, reliable temperatures 24/7.

Types of Commercial Evaporators

Depending on application, evaporators are designed differently to maximize performance:

- Ceiling-Mounted Evaporators – Ideal for cold rooms and freezers where uniform air distribution is required.

- Blast Freezer Evaporators – Designed for rapid cooling and freezing of perishable products.

- Dual Discharge Evaporators – Common in walk-in freezers and large cold rooms for efficient air circulation.

- Low Velocity Evaporators – Used in applications like ripening chambers where gentle airflow is essential.

Key Technical Considerations

When selecting a commercial evaporator, several factors must be evaluated:

- Capacity (TR/kW): Must align with room size, insulation, and product load.

- Fin Spacing (FPI): Wider spacing prevents frost buildup in freezers; closer spacing improves efficiency in higher-temperature rooms.

- Air Throw & Velocity: Determines how evenly the cold air spreads.

- Defrost Method: Electric, hot gas, or water defrost systems maintain performance.

- Material & Coating: Corrosion-resistant coatings (e.g., epoxy) extend lifespan in humid or food-grade environments.

Why ColdTech Evaporators?

At ColdTech, we design evaporators with:

- Energy-Efficient Motors for reduced power consumption.

- Optimized Coil Designs for maximum heat transfer.

- Durable Construction to withstand tough industrial conditions.

- Custom-Built Options tailored for cold rooms, blast freezers, and specialized storage applications.

Applications Across Industries

Our commercial evaporators serve a wide range of sectors:

- Cold storage warehouses

- Supermarkets & retail chains

- Food processing plants

- Hotels & restaurants

- Pharmaceutical storage

- Dairy & beverage facilities

Conclusion

A reliable evaporator is not just a part of your refrigeration system—it is the heart of cold storage performance. At ColdTech Group, we combine technical expertise, innovative design, and robust engineering to deliver evaporators that keep your business running smoothly, efficiently, and reliably.

Recent Comments